What is BCORE

BCORE “composite embedment” technology heating method is to hide the heating element and embed it in ceramics. It adopts a cotton-free structure and a cup-shaped heating design, making the atomization process faster and more uniform, the smoke more exquisite, and the heating element more efficient.

Compared with storing oil in cotton, oil in BCORE is stored in ceramic material, which effectively controls the speed of absorbing oil. Most importantly, previous technology which stores oil in cotton results in the trivial work of choosing oil holes, while in Bcore, no more hole size worries! One cartridge is compatible with different oil viscosities!

It is not difficult to discover that the heating elements and ceramic heating bodies now available on the market are mostly produced using a thick printing technique. The emergence of thick printing technology advanced the atomization technology of heating the body to a high level. Advanced ceramic matrix has the characteristics of high temperature resistance, quick oil conduction, a larger heating surface, uniform heat distribution, and so on, which greatly enhanced the flavor of vaping.

The “composite embedment” burning technology is used in BCORE heating technology. The metal sheet is first put into the mold, and then the ceramic slurry is poured into it. The mold is then sanitized, and the metal sheet is sintered at a high temperature of 800°C. No danger of slipping off occurs. In addition to the benefits of a post-membrane ceramic heating body in general, the resistance value is more stable and precisely adjustable; the heating element does not come into direct contact with the oil, further enhancing the degree of oil flavor reduction.

Why BCORE

Composite embedment technology re-endows the new definition of the ceramic atomizing core; it is not only a technical innovation but also offers benefits for the user experience and the qualities of the final product:

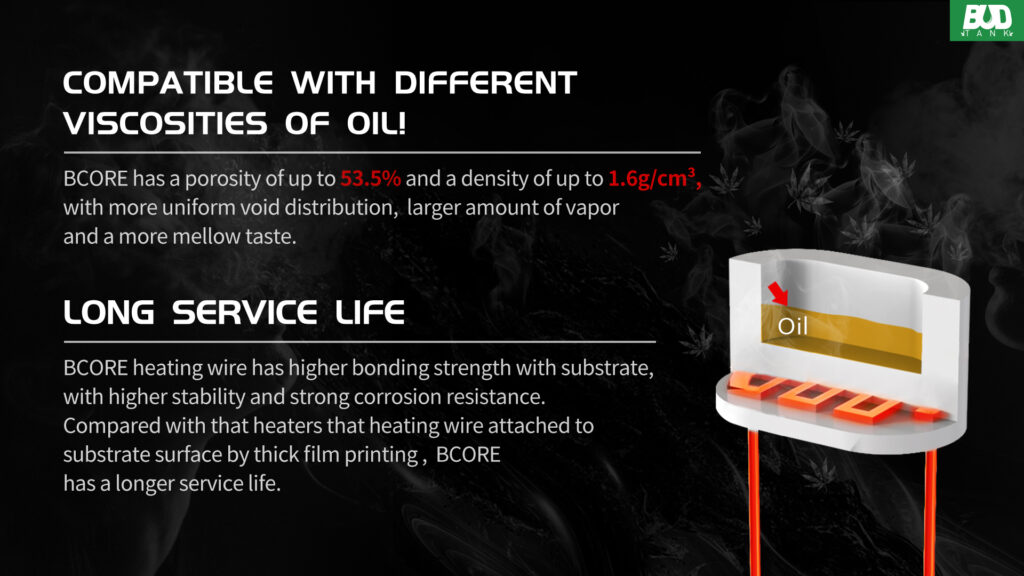

Suitable for Different Concentrations of Oil

With the “composite embedment” technique used by BCORE, the heating element does not come into direct contact with the e-liquid; the oil storage is completed through the formula of the ceramic substrate, which effectively controls the heating speed of the e-liquid. With a porosity of up to 53.5% and a density of up to 1.6g/cm³, BCORE is designed to accept different oil viscosities. Allowing users full freedom when choosing their oils, without having to be constrained to a single brand or product.

Under the same conditions, after 4 hours of heating, certain thick-film printing heating elements on the market experience oil leakage. Using its “composite embedment” technology, BCORE can effectively avoid oil leaks.

Full Vaporization and Purer Taste

Because BCORE uses the “composite embedment” method with nickel-chromium wires, its stability and temperature control capabilities are better achieved. In addition, the heating element is directly combined with the ceramic and is embedded separately on both sides and the bottom of the ceramic substrate. The distribution of the heating area is more uniform, the heating area is larger, and the heating speed is faster, so that the atomization effect is more sufficient, which provides a strong guarantee for the reduction of the taste of the e-liquid, and the taste is more mellow.

Long-lasting of use

BCORE is exclusively made with a composite of silica and alumina, compared to competitors which only use alumina. This composite enhances the strength of the atomizing core, turning it into a not-easily-breakable device while granting a longer lifespan. The BCORE atomizing core is made of “composite embedding” technology, which effectively overcomes the shortcoming of the heating element’s rapid thermal attenuation caused by the physical characteristics of thermal expansion and contraction of the material, thus prolonging the service life of the heating element.

Material Selection

All of our products have successfully passed the heavy metals tests that are established by the U.S. Authoritative Laboratories as an Industry standard. BCORE’s materials were specially sourced to conform to international food safety standards. Making its usage 100% safe.